We have 3 different solutions for installing water underfloor heating pipes in between joisted/suspended floors

Pipe spacing to be 200mm apart or less. This means you need to select a conservatory style kit or a multiple room kit – standard room kits are designed with the pipe spacing at 250mm centers which would mean you would not have enough pipe in the kit.

Spreader plate system

- A standard installation for this system assuming the joists are deep enough would be to fix batons to the sides of the joists (about 70mm from the top of the joist) then a 50mm foiled faced insulation like celotex/kingspan is cut and placed onto the batons, the pipe work is then clipped directly into the spreader plates.

- Then the pipe work is clipped directly to it, once the pipework has been tested it is then covered with either a sand and cement screed or a pumped anhydrite screed.

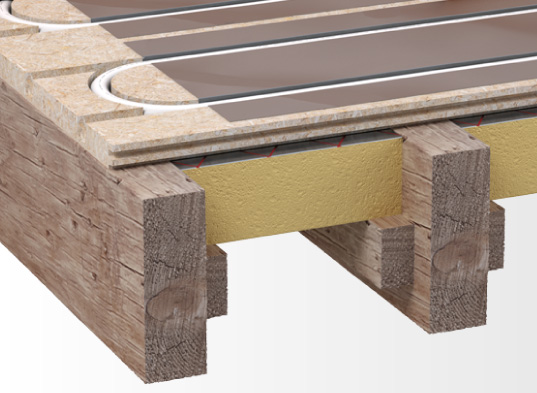

In Joist foil boards

- These unique boards combined the idea of both the spreader plate and insulation in one system, the 50mm thick XPS insulation panel has the grooves pre formed in them at 200mm centers, the whole board is then covered with an aluminum foil designed to dissipate the heat evenly over the floor above.

- A standard installation for this system assuming the joists are deep enough would be to fix batons to the sides of the joists (about 70mm from the top of the joist) then place the boards on top of the batons, the pipes can then be clipped directly into the grooves.

ProFloor

- ProFloor End Return Panels are used with the ProFloor pre-grooved panels to allow the underfloor heating pipes to run back into room, offering an easy installation of water circulation heating systems in timber suspended floor structures with no greater spacings of 400mm centres.

- This system is based on pre-grooved flooring panels for 16mm pipe, ProFloor End Return Panels provides savings both in material costs and installation time. The board is quick and easy to install and uses no extra adhesive, meaning no extra drying time is required.